Amazon Unveils Vulcan: A New Era of Warehouse Robotics

Amazon has introduced a groundbreaking robotic system known as Vulcan, designed to improve the efficiency of its warehouse operations by utilizing touch-sensitive technology to identify and retrieve products from shelves.

The Innovation Behind Vulcan

Vulcan represents a significant advancement in robotic capabilities, incorporating tactile sensors that allow it to interact more effectively with items stored in Amazon’s fulfillment centers. According to Aaron Parness, Amazon’s director of robotics AI, this technology enables the robot to manipulate objects more delicately than traditional robotic systems. “When you’re trying to stow [or pick] items in one of these pods, you can’t really do that task without making contact with the other items,” he states.

Description and Functionality

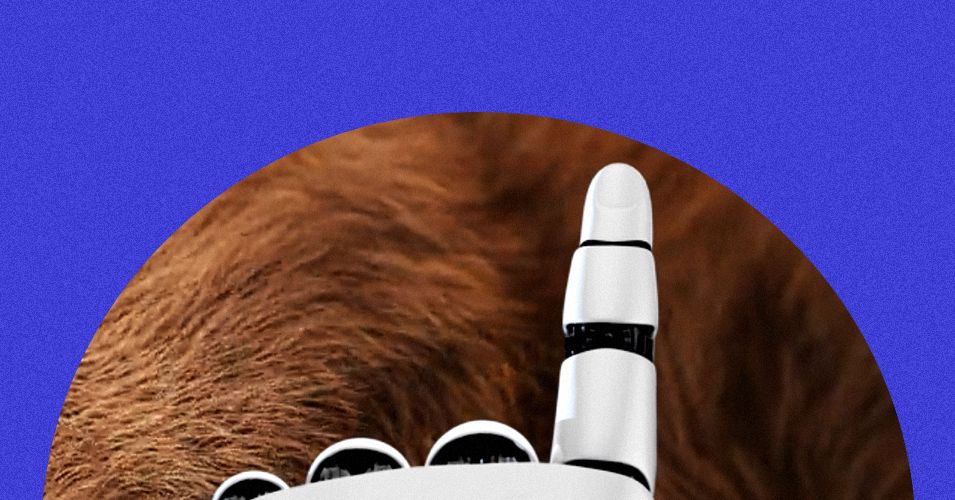

The Vulcan system combines a standard robotic arm with a specialized spatula-like appendage. This design allows it to probe shelves and a suction mechanism for pulling out items. The robot is equipped with sensors on its joints to detect the shapes and edges of objects. Parness emphasizes that machine learning plays a crucial role in interpreting sensor data and contributing to the robot’s decision-making algorithms. “The special sauce we have is the software interpretation of the force torque, and how we wrap those into our control loop and into our motion plans,” he explains.

Deployment of Vulcan

Vulcan was revealed at a fulfillment center in Hamburg, Germany, with reports indicating that it is already operational at this facility and another location in Spokane, Washington. The robot is positioned to work alongside human employees, alleviating their workload by handling items that are difficult to reach, whether high or low on shelves.

Collaboration Between Humans and Robots

As Amazon continues to augment automation within its vast network of fulfillment centers, Vulcan’s introduction marks an important shift in how human workers and robots might collaborate in the future. Parness notes that while automation is increasing, a complete reliance on robots is not the goal. “We don’t really believe in 100 percent automation, or lights out fulfillment,” he asserts. “We can get to 75 percent and have robots working alongside our employees, and the sum would be greater [than either working alone].”

Future Implications

Experts like Ken Goldberg, a roboticist at the University of California, Berkeley, recognize the significance of Vulcan in advancing the capabilities of robotic systems. “Amazon stores many different products in bins, so rummaging is necessary to pull out a specific object to fill an order,” he remarks, expressing curiosity regarding the performance of this new system. However, he also warns that while robotic touch sensing has made strides, achieving human-like tactile sensitivity remains a challenge. “The human sense of touch is extremely sensitive and complex, with a huge dynamic range,” he adds, suggesting that breakthroughs in this area may take several years.

Conclusion

With the introduction of Vulcan, Amazon is poised to enhance operational efficiency in its fulfillment centers. This state-of-the-art robotic system not only highlights the company’s commitment to innovation but also sets the stage for further advancements in the realm of robotics and automation within the logistics industry.